Hose Knitting Machine - High Speed Online

DOWNLOAD LEAFLET

Hose Knitting Machine - Continuous Process

Penguin Hose Knitting machine is used for knit-reinforced hoses used extensively in automobiles as radiator hoses and for similar low pressure applications.

This machine is characterized by high productivity, simplicity and excellent performance.

The knitting is done over the inner lining. The machine can be used with both cotton or rayon yarn. The knitting process is closely controlled to ensure a perfect knit structure that is built over the hose at suitable tensions. Thus high performance can be achieved from the end product. The machine is provided with ergonomically located controls and workspace. The centerline of the machine can be adjusted so that hoses of different diameter can be made to rest on the roller stands conveniently.

The machine operates with belt drive, with infinitely variable electric motor, which ensures quite running. The knitted layer provides excellent internal reinforcement and provides superior adhesion of the two rubber layers. Penguin hose knitting machine is highly recommended for automotive, rubber and ancillary industries.

Specifications

| Number of feeders | 8 | |

| Yarn content / bobbin | 5 kg max. | |

| Maximum diameter of knitted hose | 10 - 80 mm (other sizes optional) | |

| Bobbin dimensions (Ø x L) | 240 x 260 mm | |

| Knitting module power | 7.5 HP | |

| Caterpillar power | 2 HP | |

| Interchangeable heads | Optional | |

| Head speed | upto 400 rpm | |

| Type of needle | Crank type | |

| Line speed | Upto 20 m / min. (depending on pitch) | |

| Knitted reinforcement | Circular knitting type, plain stitch | |

| Yarn type | Dipped or un-dipped (Aramid, Polyester, Rayon) | |

| Yarn package type | Cross-wound on cylindrical standard bobbins type | |

| Rubber types | EPDM, NBR, NBR/PVC, CR, EACM, CSM, CPE . | |

| Knitted hose types | Radiator hoses, fuel hoses and other hoses | |

| Power supply | 380 - 440V, Three phase, 50 - 60 Hz | |

| Electronic Control | PLC & 4” HMI | |

| * Note: The line speed is depending on hose diameter, pitch / stitch size, rubber compound and viscosity, die resistance, max. allowed output temperature etc. | ||

-

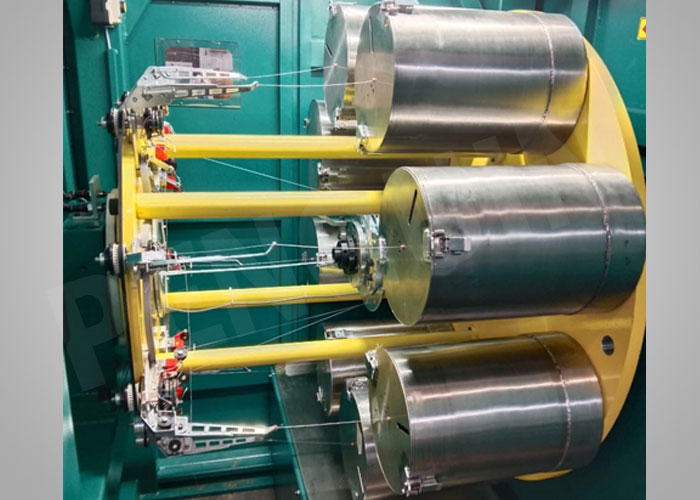

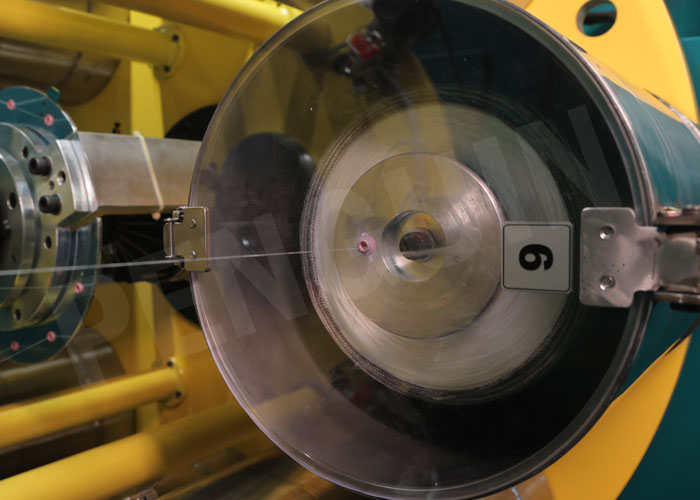

Bobbin drums

-

Positive Storage Feeders

-

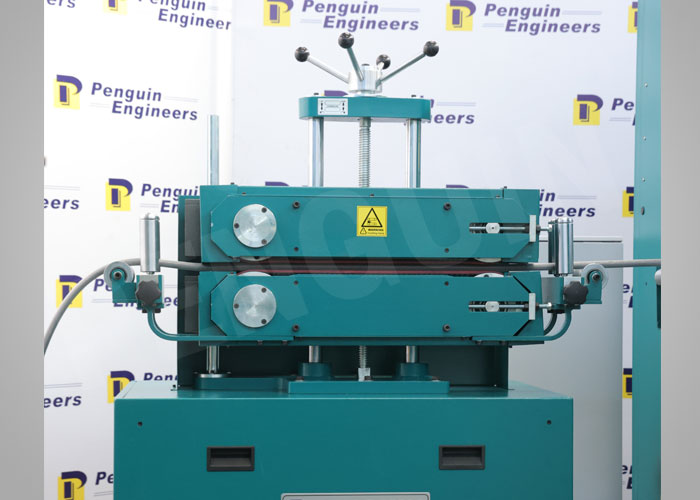

Caterpillar

-

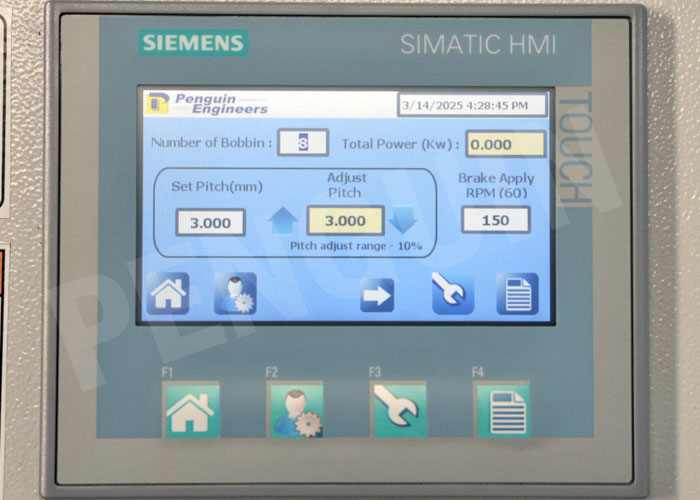

Human Machine Interface

-

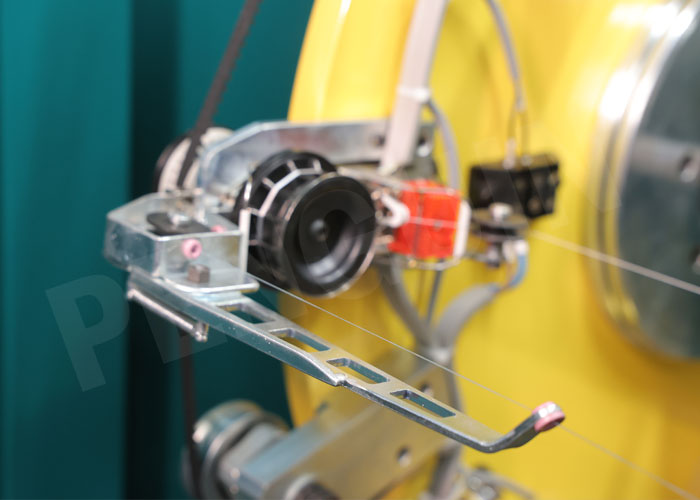

Positive storage feeder

-

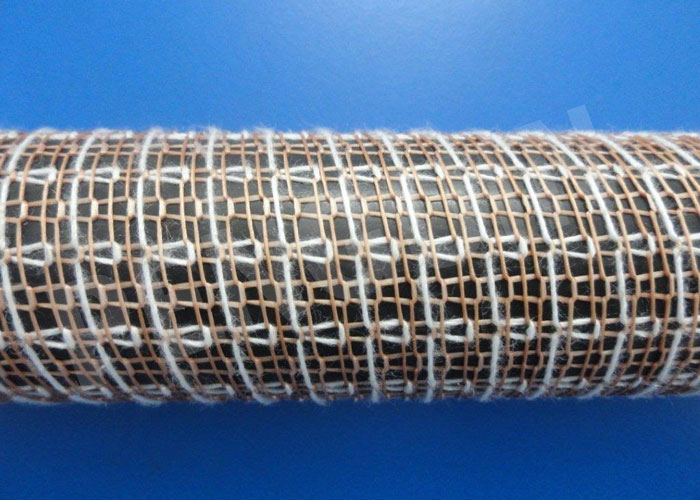

Knitting hose

-

Yarn cone bobbin drums

-

Control panel with HMI

-

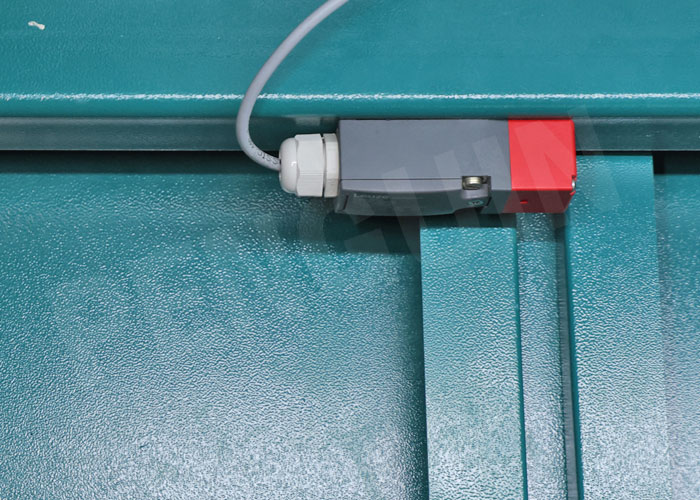

Door safety limit switch

-

Slip ring

-

Dancer arm assembly

-

Lock Stitch

-

Pneumatic caliper brake

Features of Hose Knitting Machine - Continuous Online Process

- Suitable for low-medium pressure knitted hose

- Minimum distortion from the manufacturing process

- Photo sensor stop motion for yarn cut

- Precision cams for efficient knitting

- Large yarn capacity - Big bobbins

- Variable speed drive

- Precision pulling caterpillar

- HMI - Multi function

- Rope pulley for interchangeable Knitting head

- Use of Economical and sturdy knitting needles

- Front door opening protected with safety switch

- Automatic PLC Control system

- Pneumatic caliper brake

- Dancer control

- Positive storage feeder

- Pulley block beam for head change

- Needle flap break sensor

- Sturdily built rigid structure with enclosures

- Contact length - 600mm, width 76mm

- Linatex coated timing belt

- Control system with communication to the knitting machine drive

- Speed adjustment by potentiometer with digital display

- Encoder for measuring real product speed

- Hose guide assembly at both the ends of caterpillar

KNITTING MACHINE

CATERPILLAR

Looking for an Adequate Solution for your Company?

Contact us today for free consultation or more information.

Contact Us© 2021 PENGUIN ENGINEERS